Available in a wide variety of metals and hardnesses up to 400BHN

Shaftless Flight Additional Features

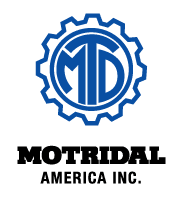

Drive Couplings

Manufactured to your specifications, to meet your field of application requirements drive couplings are connected to a gear reducer and a motor that keep the shaftless spiral in rotation. Drive plates and drive shafts provide an unbreakable connection and precise alignment. Here are some examples:

Subsections Ends

Shaftless screws are manufactured at required lengths or in subsections. Ends can be grinded and/or beveled to aid proper connections. Once welded into the final required length, Inner/Outer out-of-phase ends ensure a greater torque resistance to long spiral sections. Here are some examples:

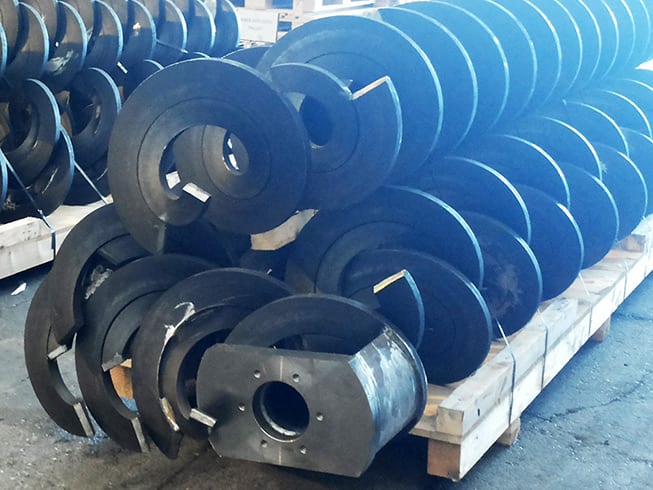

Variable Pitch

Motridal America’s revolutionary technology allows us to roll spirals with variable pitches. Available from 1/2 to 40 (inch) and can change 5 times (!) In the same subsection.

Inclined Shaftless Flight

Motridal America’s range of feasibility has no boundaries, our cutting-edge technology makes it possible to construct non perpendicular shaftless spirals.

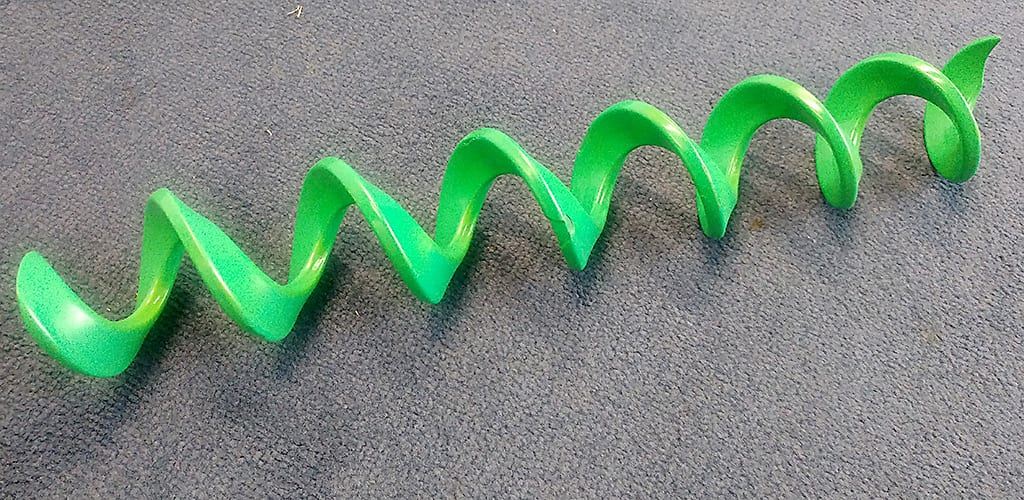

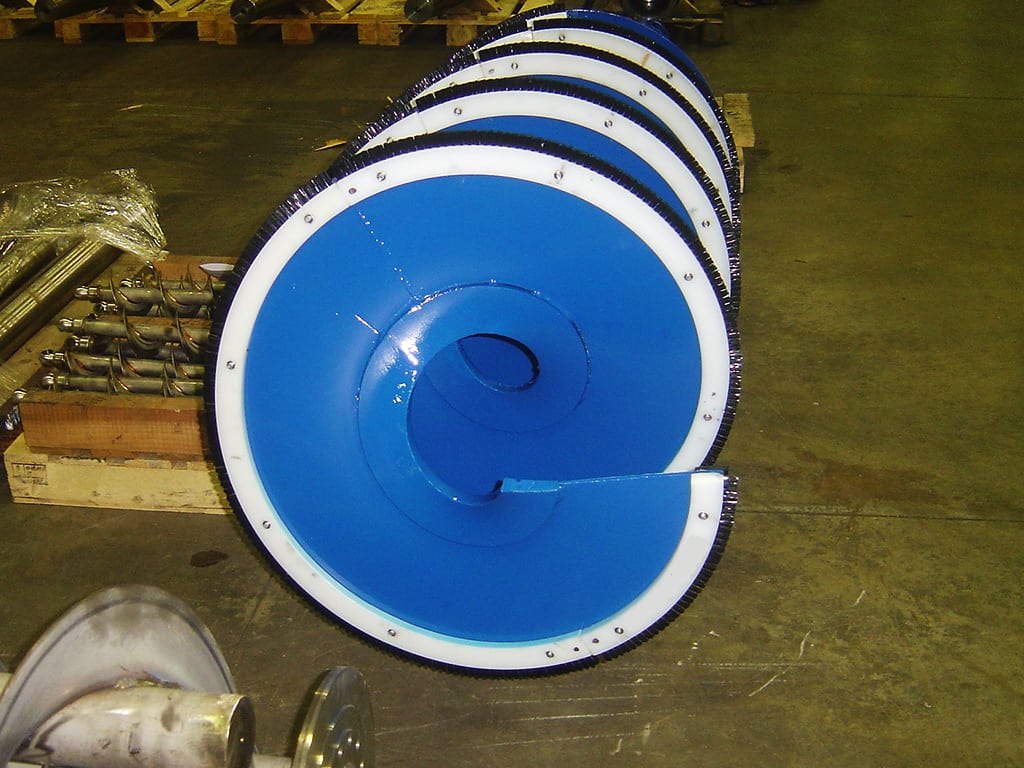

Brush-equipped Spiral

Motridal do of course also produce spirals with brushes if your applications so requires.

According to client’s needs, spirals can be machined with holes or slots to host brushes.

Brushes are bolted or clamped onto the shaftless spiral to provide cleaning transport.

Shafted/Ribbon – Shaftless Flight

Continuous spirals from flat bars can replace sectional flights in shafted and ribbon applications. This solution ensures precision and tight tolerances. Assembling and welding times decrease significantly; the economic advantage is not so marginal.

Shaftless Conveyor

Motridal America supplies the main local and international manufacturer of shaftless conveyors. If you are looking for the complete machine do not hesitate to contact us. We can get you in touch with one of our well-established Partners. We believe in collaboration!

Surface Treated Spiral

Motridal is capable of ensuring a huge range of industrial processes that alter the surface of a manufactured item to achieve a certain property.

Machined Spiral

According to client’s specs, spirals can be machined for custom applications. They may be tapered or have holes to host additional components.

Hardfaced Spiral

For each industrial application, may be applied to a new part during production to increase its wear resistance.

Painting

According to your specifications, various finishes are available for your spiral surfaces. Common examples are blast cleaning or primer. We also offer two special finishes, metallic zinc rich epoxy primer and hydrophobic polyurethane coatings, which provide excellent protection for steel substrates in wastewater environments.

Packaging & Shipping

Packges customization is a further benefit. Tailor-made crates and reinforced skids ensure transport costs savings. ISPM-15 Heat Treated pallets come with all the goods shipped internationally.

Under the Incoterms 2020 rules, Motridal America either can offer FCA or DAP services through its reliable carriers.