Custom-made in a wide variety of sizes with our inhouse cutting edge technology.

Sectional Flight

For every need and application

, manufactured in a wide range of dimensions and materials, with the possibility of reaching up to 200” in diameter and greater, and thicknesses as large as 3-1/2”.

Flexibility, experience and cutting edge technology, such as new laser cut and auger flight press machines for the flight forming, make it possible to construct cylindrical, conical, specially shaped, machine worked and drilled helical forged flights.

This process is applied when a continuous spiral cannot be manufactured due to the limitations that come with the physical and mechanical properties of the material itself. Available in both right and left hand, formed either cold or hot press that is cut out from steel sheet. Through this method we can produce uniform blades and thicknesses. The individual sectional flights are then assembled on to the pipe, welded and fastened by intermittent or continuous welds that form an uninterrupted helix flight.

up to 200 inch diameter

Thicknesses as large as 3-1/2 inches.

We also produce drive plates and drive shafts in various configurations.

Normally manufactured in carbon steel,

but we offer a wide of variety metals including but not limited to high tensile micro-alloyed steels (HTMAS), abrasion resistant steel and stainless steel. For all those special applications where abrasion and corrosion are a threat to the life expectancy of the components we offer the solution of manufacturing flights that consist of only one common steel base, and a coating surface in tungsten or chromium carbide.

We are currently one of the few companies who can manufacture flights with large diameters in a single section with the possibility of reaching a width of 55 inches in metal strip and greater instead of manufacturing and welding multi-pieces together in sequence. Furthermore, with our cutting edge technology we are able to shape materials with thicknesses greater than 3 inches, that generally are used for drilling and nuclear applications. Upon request, flights can be beveled on both ends to ensure proper connections.

Final products meet rigid manufacturing quality standards.

All Motridal America welders are certified in accordance with American Welding Society (AWS) Codes.

We do not have a standard; we truly CUSTOMIZE all our spirals to FIT CLIENTS’ NEEDS.

Motridal America can easily operate in both imperial and metric systems of measurement.

Our R&D ensures that our ranges of feasibility are constantly expanding. Our current data:

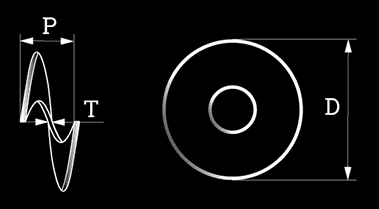

Outer Diameter (D): 1 – 200 (inch)

Outer Diameter (D): 1 – 200 (inch)

Pitch (P): 3/8 – 700 (inch)

Thickness (T): 1/8 – 3-1/2 (inch)

Our broad network ensures worldwide raw material procurement.

Our cutting edge technology ensures the forming of various Brinell Hardnesses of up to 1000 BHN. Our broad network allows us to procure raw material worldwide.

|

Available materials:

|

|

Motridal America has direct access to many markets, we can easily procure alternative materials as the European grades S355J2 (number 1.0577), St52-3 (number 1.0570) and special micro-alloyed Swedish steels.

We exceed industry standards and are extremely capable of meeting all your needs. Each batch will have specific tolerances, in general we can refer to the common values below.

|

Available materials:

|

MOTRIDAL America uses the latest technology and engineering software to support its high quality production.

- Agriculture (manure, cereals, vegetables)

- Drilling (soil, sand, gravels)

- Wastewater treatment (slaughter waste, garbage, sludge)

- Pulp & Paper (fibre sludge, pulper reject, wood chips)

- Plastics (granulate, chips, capsules)

- Construction (concrete, asphalt, sand)

- Food (sugar, salt, grain)

- Chemicals (granulate, capsules, fly ash)

- Biomass (wood chips, pellets, saw dust)

- Mining (sand, stone dust, carbonides)

High Diameters

With our cutting edge made in house technology we can manufacture single-piece spiral sections of up to 200 inches and higher for the outer diameter. Generally intended for screw pumps/turbines and drilling applications without necessarily needing a multi-pieces welding in sequence to reach the desired outer diameter.

High Thickness

In order to manufacture spirals with thickness greater than 3 inches we combine our high power presses and the heated raw material. Our finished product/component is used in applications with extremely heavy usage.

Accuracy

The quality of our auger blades is superlative, we meet the most demanding tolerances clients care about. We exceed industry standards and meet your specifications perfectly. We place emphasis on in-process inspection capabilities, this is a know-how in which you can be confident.

Find below proper solutions to the most common problems:

- Flights not gapped around the pipe

- Flights ends not misaligned

- Flights ends not gapped

- Flights planarity and perpendicularity with the pipe.

Flights not gapped around the pipe

Flights ends not misaligned

Flights ends not gapped

Flights planarity and perpendicularity with the pipe