Customized in a great variety of sizes to fit clients' needs.

Shaftless Flight

Manufactured to your specifications

with diameters up to 35”, a multitude of bar sizes and custom configurations available. Our spirals are made of high tensile micro-alloyed steel (HTMAS) that’s cold formed using both single and two stage forming processes. Brinell Hardness up to 400 BHN is available. We also manufacture spirals in a wide variety of metals including but not limited to abrasion resistant steels and stainless steel. Need continuous spirals with variable pitches? Ours can change up to five times in each subsection.

up to 35 inch diameter

Brinell Hardness up to 400 BHN

We also produce drive plates and drive shafts in various configurations.

Depending on the design application,

spirals are manufactured with single or multiple bars of stacked flights coaxially welded together. At your specification , spirals are supplied at the required length or in subsections. Motridal America shaftless flights are beveled on both ends to ensure proper connections. On request, in the inner/outer configurations, the internal spiral of each following subsection is longer than the outer one in order to misalign the weld and increase the overall strength.

This centerless screw makes a conveying system particularly suitable for materials that tend to tangle with a shafted spiral. It ensures reliable and efficient material handling with low life-cycle costs.

Final products meet rigid manufacturing quality standards.

All Motridal America welders are certified in accordance with American Welding Society (AWS) Codes.

We do not have a standard; we truly CUSTOMIZE all our spirals to FIT CLIENTS’ NEEDS.

Motridal America can easily operate in both imperial and metric systems of measurement.

Our R&D ensures that our ranges of feasibility are constantly expanding. Our current data:

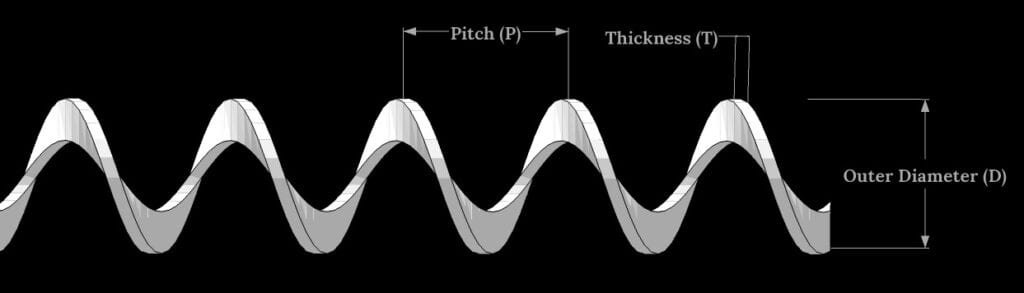

Outer Diameter (D): 1 – 35 (inch)

Outer Diameter (D): 1 – 35 (inch)

Pitch (P): 1/2 – 40 (inch)

Thickness (T): 1/8 – 1-1/2 (inch)

Our broad network ensures worldwide raw material procurement.

Our cutting-edge technology assures the rolling of various Brinell Hardnesses up to 400 BHN.

|

Example of available materials:

|

|

Motridal America has direct access to many markets, we can easily procure alternative materials as the European grades S355J2 (number 1.0577), St52-3 (number 1.0570) and special micro-alloyed Swedish steels.

- Wastewater treatment (slaughter waste, garbage, sludge)

- Pulp & Paper (fibre sludge, pulper reject, wood chips)

- Food (sugar, salt, grain)

- Chemicals (granulate, capsules, fly ash)Biomass (wood chips, pellets, sawn dust)

- Mining (sand, stone dust, carbonides)

Configurations

Spirals are manufactured with single or multiple bars of flanked and/or stacked flights welded together. Shaftless screws can also be manufactured as a combination of continuous and sectional flights. Here are some configuration examples:

Cross-section

Tensile forces in forming process shapes flat bars from a rectangular cross section to a tapered one.

Shapes & Positioning

Spirals are produced from a flat bar in a multitude of diameters and pitches. Flat bars can have different shapes and can be oriented in different ways. These are not limited to the ones listed below.